Direct Metal Laser Sintering (DMLS) Technology

Most of you might have heard about 3D printing of plastics, but for sure, only some of you will be aware of 3D printing of metals.Yes, you might have denied this truth a few decades ago, but now 3D printing of metals has emerged as a reality. Throwback to 1990, the innovation of Direct Metal Laser Sintering (DMLS) was associated with the Selective Laser Sintering (SLS), and soon after the mainstreaming of SLS, DMLS had also come under the spotlight. The first DMLS printer went on the scene in 1995.

Meanwhile, going deeper into the details, it is evident that DMLS is one of those few techniques that can create an original 3D model part with the assistance of its 3D computer model. This process is a modified form of powder metallurgy (PM), which is a properly developed metal- molding technology that utilizes pressure and heat to make powdered metal parts.

Depending on 3D model, the metal part will gain shape layer by layer as it happens in the SLS process. But, the most significant difference comes up in the form of temperature, as working with plastics, the sintering temperature is 160°C to 200°C, while this temperate is 1520°C to 1600°C in case of metals. In short, you need a much more high-wattage laser to meet this criterion.

Working Material Used For DMLS Technology

The working material for this 3D metal printing process is finely powdered metal. Typically, the size of metal particles must not exceed 20 to 40 micrometers, as the size of the particles has a great impact on the final part. The lesser will be the particle size finer will be the final part. Moreover, other factors that are important to determine the quality of the final part are the size of the layer spot and the laser height.

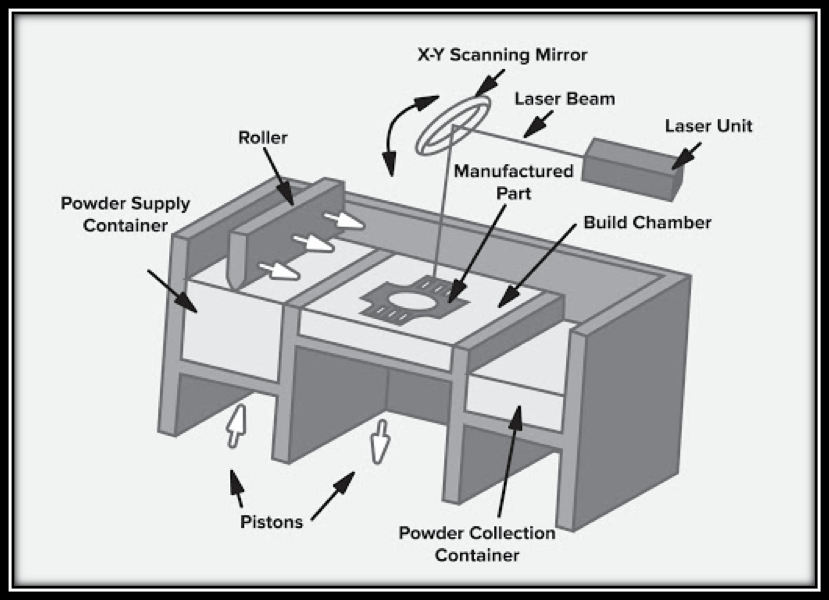

How Does DMLS Technology Work?

Having an idea about the groundbreaking technique, here is a proper working mechanism of DMLS;

Step 1: The hopper of the DMLS printer is filled with the metal powder. The powder reaches the required temperature with the help of heaters for sintering.

Step 2: The process begins as a thin layer of powdered material that falls on the platform, and laser starts following this layer and keeps on sintering powder into the solid. The process remains to continue until it ends.

Step 3: After the completion of phase 2, the part is left to cool, and powder of loose metal is cleaned from the printer.

Step 4: This is the last step, and it belongs to the removal of support.

Now, the prepared part is ready to be taken as any normal metal part, and you can perform any operation on it without any concern.

Advantages of DMLS Technology

Here are some of the benefits associated with the DMLS Technology:

- It can directly produce metal parts.

- A diverse range of metal and metal alloy is available for processing. Steel, stainless steel, titanium, and many other metals and alloys are compatible with this process.

- The unused metal powder remains safe, and you can use it again.

So, that is a complete overview of DMLS technology, and having read the post, you will be well convinced about the efficiency of this manufacturing process.